Welcome to Rads Global

Responsibly Innovating Towards the Sustainable Futures

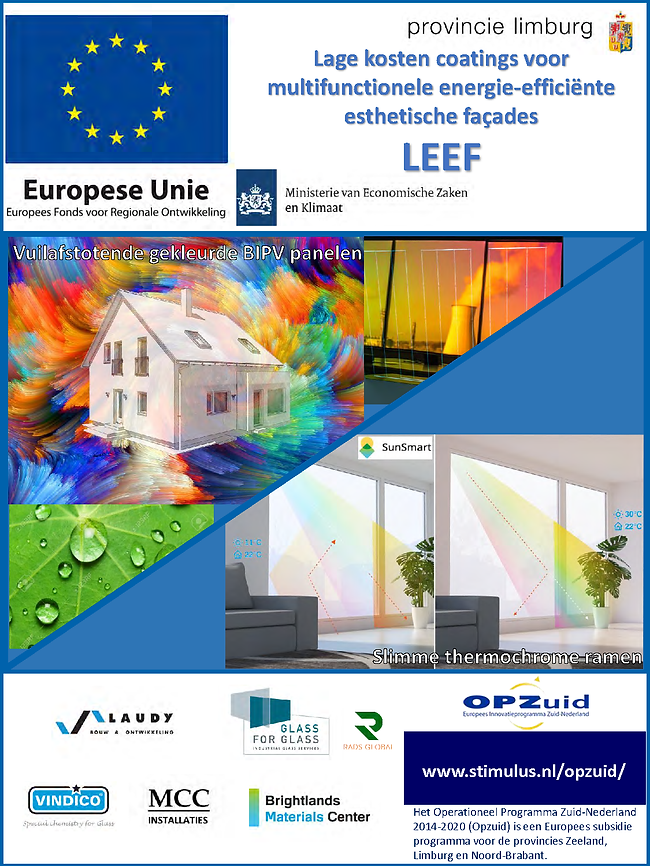

Rads Global is a leading provider of glass coatings for a variety of applications. The Patented Multifunctional Nano Coatings from Rads Global address the problems with the functions of Antisoiling, Anticorrosion, Anti-abrasion, Antireflection (ARC), Antiglare, Sodium migration barrier (Anti PID), Self Cleaning, Anti-biofilm and anti-dripping. The antisoiling coating is an emerging innovation for glass applications in different sectors. The glass industry has been regarded lagard in the development of new technologies and investing in new research on glass technologies. We have invested and visioned for innovating responsibly for the sustainable futures of lives and way of living on the earth. We are able to lead technological development from the front and offer solutions to numerous problems for glass applications with different functionalities. Our innovative coatings are designed to improve the performance and durability of glass products, BIPV, PV modules, and Solar Mirrors. We strive to stay ahead of the curve by continuously researching and developing new coatings and technologies. Our goal is to provide our clients with the highest quality and most reliable products available.

Why Coatings are critical?

The glass is used as a protection and media of transfer of light in different applications in Industry, buildings, Household, Machines, Vehicles, Electronic Displays, Ships, airplanes, PV modules, and Greenhouse. The philosophy and science behind the protection could not recognize that who should "Protect the Protector"! We are able to foresight and vision for the "Protection of the Protector"! This enables us to innovate responsibly by developing different protection technologies to protect the glass surface against corrosion, abrasion, reflection, soiling, cementing, osmosis, scaling, and drippings. We have Patented Nano-Technologies with multiple functionalities for application in different areas. These technologies enhance the life, performance, protectability, safety, and quality of glass applications.

Why Coatings are critical for PID in PV modules ?

What is sodium migration/PID in PVmdoules? How Potentially Induced Degradation is caused by sodium migration? How patented Coating technology prevent PID?

The origin of Na+ contamination is fairly clear. In most of the research findings, it has been concluded that the Na+ contamination originates from the glass sheet. The solar glass contains 72 to 75% SiO, 13% to 14% Na2O, and 11 to 13% Ca O. The bulk of the resistivity in the range of 10 to the power 10 to 11Ω cm at 250C Solar Glass, in Solar glass is facilitated by Na+. The Na+ migration and presence in glass contribute maximum to the Potentially induced degradation (PID) in PV modules. The performance of PV modules can be reduced up to 30% due to PID. It is proven by research and technological deployment that the Si-O-Si layer on the surface has been highly effective in creating a barrier in the migration of Na+ and curtailing the PID.

Multifunctional Patented Coating Technology brings a layer of Si-O-Si on the glass surface on both sides of the solar glass which makes it a highly effective solution to address the serious problem of PID. The PID problems are more serious in BIPV/ Bifacial PV modules due to double usage of glass. These innovations demand more urgently to deploy a coating that can provide a safety shield to Cells and prevent modules from PID.

Antisoiling Coating: Why and How is it important for PV Modules?

The Glass Surface of the PV module receives lots of soil in field conditions. Soil is removed from the surface by wet or dry cleaning in solar power plants as a standards practice. Wet cleaning requires a large quantity of water for cleaning. This water demand makes solar power unsustainable to the extent of cleaner water usage. However, Antisoling coating can reduce this requirement of water by 70% with the increase in the performance of the PV modules. Antisoiling Coating functions as a self-cleaning agent for the surface of the PV modules for 25 years. This lowering of soiling on the surface also leads to addressing the problem of the hot spot phenomenon. The frequency of cleaning is also reduced in the range of 50 to 70%. This leads to a reduction in O&M costs for project owners. Antisoiling Coating generates additional revenue flow for solar power projects by increasing the performance of solar power projects. This coating technology can be applied on the glass before PV module manufacturing as well as on PV modules installed in solar power projects.

Businesses

Contact Us

Rads Global Business BV

Delft, Netherlands

if you want to know more or buy our products then write us.

_1.png)